VERSATILE SOLUTIONS FOR THE HIGHEST DEMANDS.

Strong connections - precision welded.

As a specialist in welding technology, mechanical machining and precise labour work, we offer you a full service solution. Whether individual parts or complex assemblies, prototypes or series production - experience meets modern production technology.

We offer special expertise in the field of repair welding: This allows us to save damaged components reliably and economically - a real alternative to expensive new purchases.

EXPLORE OUR THREE AREAS OF EXPERTISE AND LEARN HOW WE TURN CHALLENGES INTO SOLUTIONS.

PRECISE, VERSATILE, RELIABLE.

Whether individual production or series production - we at Nibotec Fertigungstechnik are your partner for demanding welding technology. With many years of experience and state-of-the-art equipment, we produce robust welded constructions, precise assemblies and resilient components - individually tailored to your requirements.

Reliable, punctual and precise - all from a single source.

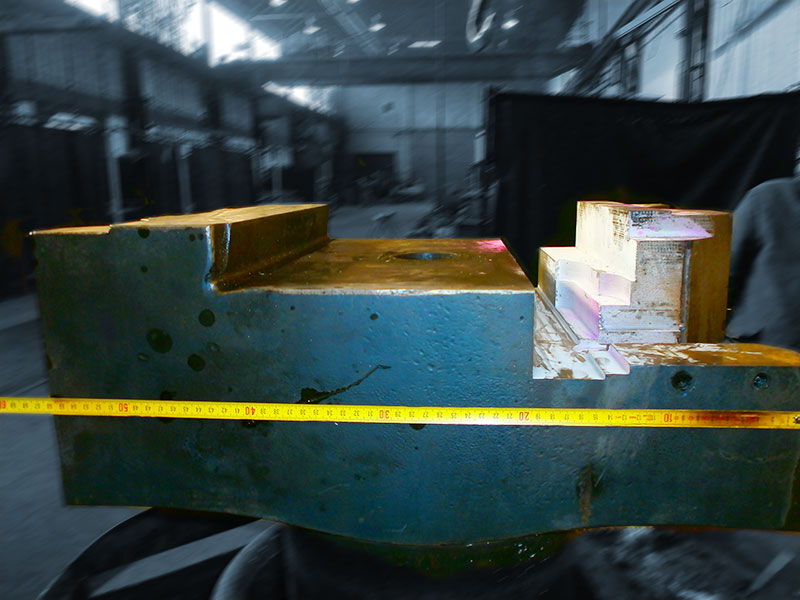

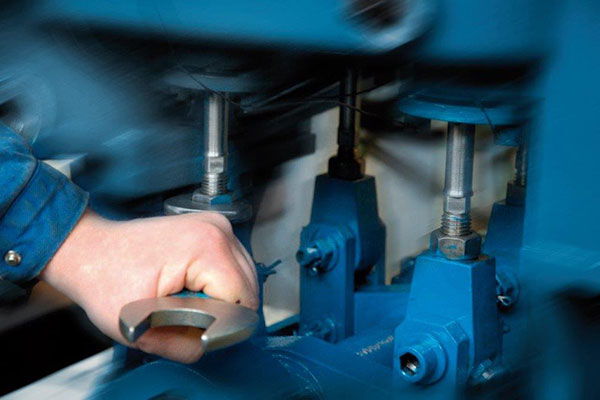

Time is money - especially in the event of machine damage. Our repair welding repairs incorrectly machined or damaged workpieces - e.g. machine bodies, forging hammers or presses - including ultrasonic testing.

Advantages for you:

- 24/7 deployment, throughout Germany and internationally

- Directly on site to reduce downtime

- Professional execution by experienced welding experts

Our service is available around the clock: 24/7, directly on site at your plant - throughout Germany and internationally. For maximum availability of your equipment with minimal downtime.

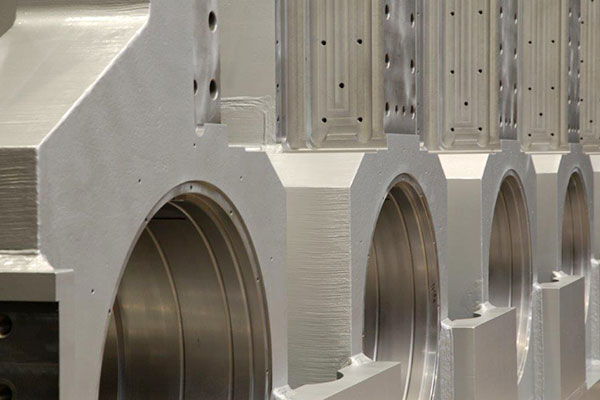

We manufacture demanding welded structures and assemblies with a unit weight of up to 50 tonnes that comply with drawings and standards. All common welding processes - MIG, MAG, TIG - are also used, depending on requirements, automatically using a welding tractor or welding robot.

Typical products are machine frames, press stands, housing constructions or internal welding arms. Our particular strength lies in the manufacture of complex peripheral parts for mechanical and plant engineering - precise, resilient and produced on time.

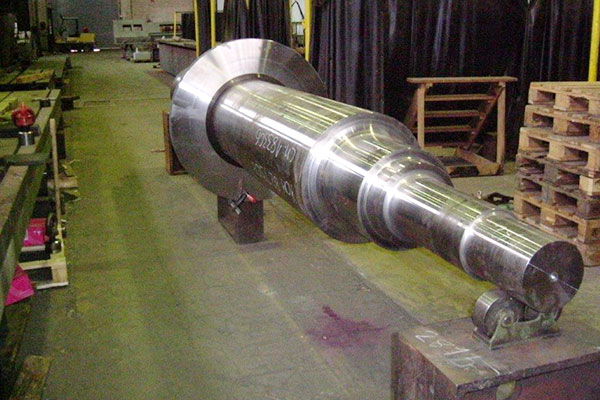

We reinforce heavily stressed components by specifically armouring hard, wear-resistant and heat-resistant layers. Whether shafts, gears or cylinders - we take care of professional metal deposition welding, e.g. for components of rotary furnaces, grinding plants, rolling mills, tools or forming technology.

Our process extends the service life of your machine components and protects them sustainably against wear, corrosion and high temperatures.

Welding different steel grades is one of our special skills. Whether high-strength special alloys, heat-resistant stainless steels or demanding tool steels - we ensure safe and resilient connections, even with difficult material combinations.

Our experience and in-depth know-how in handling special steels make us a reliable partner for high-quality welding work in sensitive application areas.

REPAIR WELDING

ARMOUR AND REPAIR - PRECISION THAT LASTS.

MACHINING

PRECISION MADE TO MEASURE.

Whether ready-to-install individual parts, complete assemblies or tailor-made spare parts: We manufacture mechanical components precisely according to your drawings - from prototypes to small or large series. Thanks to our diverse fleet of machines and an experienced partner network, we are able to respond flexibly to a wide range of requirements. This ensures consistently high quality - reliable, punctual and precisely tailored.

Our CNC lathes and milling machines (also 5-axis centres) process mild steels, alloys, stainless steels, aluminium or Inconel.

Advantages include: tight tolerances, surface quality, on-time delivery - combined with CAD/CAM support and efficient processes.

Everything from a single source - with the highest precision and reliability.

Specialist in banning spare parts and forging technology

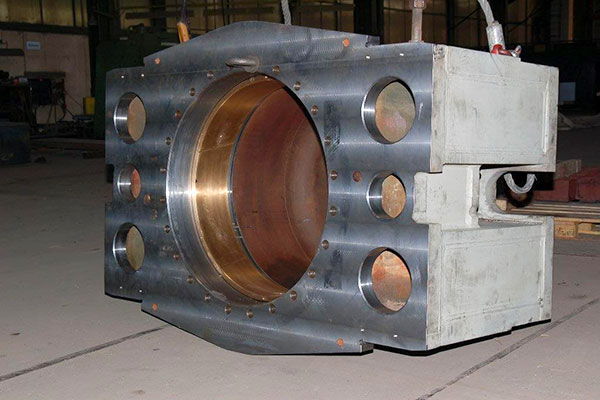

We are your competent partner for the remanufacturing and repair of high-quality spare parts for die and freeform hammers as well as tube bending machines - especially the Banning brand. Whether power amplifiers, intake and exhaust valves or control valves: Our many years of experience in machining and designing these special components guarantees the highest level of fit and functionality.

Another area of expertise is the production of bridges, stands, cylinders and valve controls for freeform hammers. We combine technical know-how with precise mechanical machining and practical design performance - individually tailored to your requirements.

We also offer reliable service in the field of repairs: Our trained specialists take care of the professional repair welding of cracks and fractures on the basic structure of your forging hammers - for example on Hammerbär or guides.

This service is available around the clock, 7 days a week. We use planned maintenance and downtime efficiently to keep it to a minimum.

Whether prototype, single piece or series production part - we manufacture precise turning and milling components to the highest quality standards. On our modern CNC lathes, milling machines and machining centres, we process a wide range of materials - from conventional mild steels to high-strength alloys.

Our manufacturing is designed for technically demanding components that require tight tolerances, complex geometries and high repeatability. We attach particular importance to dimensional accuracy, surface quality and on-time delivery.

Thanks to end-to-end CAD/CAM support, qualified specialists and efficient processes, we are able to respond flexibly to your requirements - from individual production to economical series production.

Typical areas of application for our turning and milled parts include mechanical engineering, plant engineering, energy generation, forging technology and the maintenance of production systems.

We use planned maintenance and downtime efficiently to keep downtime to a minimum.

For particularly large workpieces, we rely on the strength of our partner network: Together with experienced specialist companies, we implement the mechanical machining of components up to 160 tonnes - precisely, reliably and on time.

Whether machine bed, support structure or housing - our network partners process large parts with travel paths of up to 33 metres in length and 7 metres in width.

OVER 25 YEARS OF EXPERIENCE, PASSION AND INNOVATION.

For more than 25 years, we have combined technical expertise with craftsmanship precision. This experience makes us a strong partner for demanding manufacturing projects - from the first order to modern high-tech production. Take a look at our history and discover how we are constantly evolving and setting new standards.

FLEXIBLE WHEN YOU ARE.

Whether individual production, short-term support or complete order processing: With our extensive fleet of machines, qualified specialists and decades of experience, we reliably take on a wide range of contract work for industry, trade and maintenance. We respond quickly and flexibly to your requirements - at our premises or directly at your site.

Whether it’s a short-term order or a long-term partnership, Nibotec offers tailor-made solutions with the highest quality standards.

Internal stresses occur in the material during welding, forming or machining - these can impair the dimensional accuracy or service life of your components. With our annealing, we ensure targeted relaxation and more stability.

In our high-performance annealing furnaces, we finish your workpieces using the low-stress annealing process or hydrogen effusion annealing - entirely according to requirements. Components with dimensions of up to 6,000 x 3,000 x 2,600 mm and a weight of up to 36 tonnes are possible.

An overview of our services:

- Stress-relief heat treatment to reduce internal stresses

- Hydrogen effusion annealing to remove hydrogen deposits

- Temperature monitoring and logging according to your specifications

- On-time processing - even as part of complex production processes

Whether as a single item or a series batch - we provide

your components reliably at operating temperature.

Whether for preparation for a coating, removal of old coatings or for defined surface roughness: with our blasting, we create the optimal surface for your application. In our generously dimensioned blasting chamber (6,700 x 4,100 x 4,100 mm), we process workpieces of a wide range of sizes and geometries - efficiently and evenly.

We blast to Sa 2.5 (purity level according to DIN EN ISO 8501-1).

An overview of our services:

- Surface preparation for coating, painting or further processing

- Blasting according to Sa 2.5 or specific customer specifications

- On request: subsequent colour coating according to customer specifications

Smooth base, firm hold or perfect adhesion - with us, your surface becomes a quality feature.

Wherever your machines are located: Our experienced service team is available 24 hours a day, seven days a week - fast, reliable and worldwide. We carry out welding, conversion and repair work on machines and systems of all sizes.

Whether it’s press frames, machine housings, hot plates, forging hammers, hydraulic cylinders - we bring the know-how, equipment and the right team. Our technicians specialise in complex industrial applications and work hand in hand with your maintenance or production - for minimal downtime and maximum success.

An overview of our assembly services:

- International assignments with our own specialist staff

- Welded assembly

- Proper welding and maintenance work on site

- 24/7 emergency preparedness - also available at short notice

Rely on a partner who is there when it matters.

Even the best components only arrive when logistics and timing are right. That’s why we not only offer you high-quality production, but also a reliable and well-thought-out logistics solution - right to your destination.

We work with established logistics service providers and special transporters who can also safely move large, heavy or delicate workpieces. From simple shipping to complete project logistics - we coordinate the right transport concept for you.

Overview of our logistics services:

- Planning and organisation of transports, national and international

- Coordination with freight forwarders, special and heavy-duty logistics

- Packaging according to industry and export standards

- Appointment monitoring and communication from a single source

- As an option: Direct delivery to the construction site or production line

With Nibotec, you get the complete package of production, assembly and logistics - from a single source, cleanly coordinated and with a fixed contact person.